Quality Assurance through Material Testing Lab

Wiki Article

Mechanical Evaluating Facility: Assessing Material Efficiency

Are you curious about how products are examined for their efficiency in engineering? In this short article, we will explore the importance of product screening as well as the different mechanical tests made use of to review product efficiency.Significance of Material Screening in Design

You need to understand the relevance of product testing in design to ensure the efficiency as well as integrity of your products. Product screening is a vital action in the style and production process. By subjecting products to different tests, you can review their mechanical buildings and also figure out if they meet the called for requirements and requirements.

Material screening additionally permits you to ensure the reliability and durability of your products. By replicating real-life problems and also subjecting materials to extreme temperatures, humidity, as well as destructive atmospheres, you can examine their durability and performance with time. This aids you make educated choices concerning the products you select for your items, preventing prospective failings and also expensive recalls in the future.

In addition, product screening offers important data that can be used to improve the design as well as manufacturing procedure. By analyzing the results of various tests, you can optimize the product option, determine areas for enhancement, and boost the general quality of your items.

Kinds Of Mechanical Examinations for Examining Material Performance

When it comes to reviewing product performance, there are numerous kinds of mechanical tests that can be conducted. One usual test is the tensile examination, which determines the stamina and ductility of a product by applying stress up until it breaks. An additional test is the compression examination, which examines a material's capacity to stand up to compressive forces.

Recognizing Material Properties for Screening

Comprehending the homes of materials is necessary for conducting reliable tests. When you are reviewing material efficiency in a mechanical testing center, it is necessary to have a thorough understanding of the different properties that can impact the product's habits. One vital building to consider is the toughness of the product, which refers to its capacity to endure used pressures without breaking or warping. Toughness is generally gauged through tests such as stress or compression examinations, where the product is subjected to drawing or pressing forces until it reaches its snapping point.Another important home is solidity, which describes the product's resistance to impression or damaging. This property is crucial in figuring out the material's capability to stand up to wear and tear. Hardness can be determined utilizing different approaches, including the Brinell or Rockwell firmness tests.

Additionally, it is crucial to take into consideration the material's ductility, which is its capacity to undergo plastic deformation without fracturing. Ductility is gauged via examinations like the tensile examination, where the product is extended up until it reaches its breaking point. This building is specifically crucial in applications where the material needs to be curved or created without breaking.

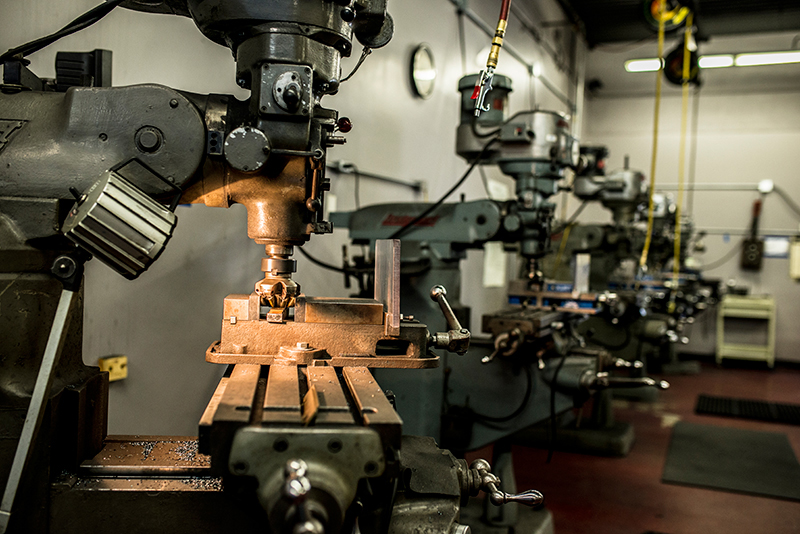

Equipment and Strategies Utilized in Mechanical Evaluating

To precisely assess the residential or commercial properties of different products, it is very important to familiarize on your own with the devices and click reference techniques made use of in mechanical testing. Among one of the most typically made use of tools is the global testing machine. This maker applies regulated forces to test the stamina, elasticity, and also other mechanical residential or commercial properties of products. It consists of a lots framework, grasps, as well as a control panel. By changing the grips as well as setting the preferred force, you can check various samplings. Another vital piece of tools is the Continue hardness tester, which gauges the resistance of a material to imprint. There are various types of solidity testers, such as Rockwell, Brinell, and Vickers, each utilizing a various technique to establish firmness. In enhancement to these machines, there are different strategies utilized in mechanical screening. Tensile testing, for instance, entails stretching a product till it breaks to determine its toughness and elasticity. Compression screening, on the various other hand, involves using pressures that squeeze the product to gauge its strength as well as security. By understanding the devices as well as strategies used in mechanical testing, you can properly assess the efficiency of various materials.Interpreting and also Studying Test Results for Material Performance Examination

When translating as well as examining examination outcomes, you'll require to meticulously examine the information to establish just how well the products carry out. Start by evaluating the mathematical worths obtained throughout testing. Look for any fads or patterns that might emerge from the data. Exist the original source any kind of considerable variations or outliers? These can show prospective issues or disparities in the product's efficiency.Next, take into consideration the certain properties being checked as well as compare them to the desired specifications or standards. Are the outcomes within the appropriate variety? Otherwise, it is essential to recognize the reasons behind any kind of discrepancies. This can involve exploring the testing technique, sample prep work, or perhaps the material itself.

Verdict

There you have it, comprehending the value of product screening in engineering is essential for assessing material performance. material testing lab. By performing numerous mechanical examinations, you can obtain useful insights into the buildings as well as habits of different materials. With the right equipment and methods, you can accurately gauge and also assess examination results to analyze product performance. Make sure to focus on product screening in your design jobs to guarantee optimal efficiency as well as reliability.Report this wiki page